Maverick 4 lug 8" rear end installation

This was a pretty straight forward swap. The old 7.25" rear had a growling pinion bearing. I drove it that way for a long time (over a year???), it finally got worse during the summer and forced me to do the swap.

One of rear ends available for the I6 Maverick was a 4 lug 8" unit. This particular rear end is the most desirable unit for old Falcon and early Mustang I6 cars. It is just slightly wider than the early Falcon rear with a 52.25" (vs 51.75") housing width. One important thing to note is that the backing plate pattern is the same as the 7.25" rear and not the 5 lug 8" rear . This means the backing plates for the wagon's 9"x2.25" drums are a direct swap for the skinny 9"x1.5" drums/plates that were stock on the Maverick. The axles are 28 spline, like the five lug axles, but, are just slightly smaller at the bearing end, and use different wheel bearings and seals than the five lug 8" rear. The shock plates also needed to be modified as the falcon 7.25 rear is a step tube rear end. The Maverick has one shock in front and one shock behind the axle, so those plates are useless (one of them anyway).

My shopping list for this swap was:

Mav 8" rear hub to hub ... $100 pick-n-pull

2.75" round end U-bolt set 6.75" long ... $6.50 each at NAPA

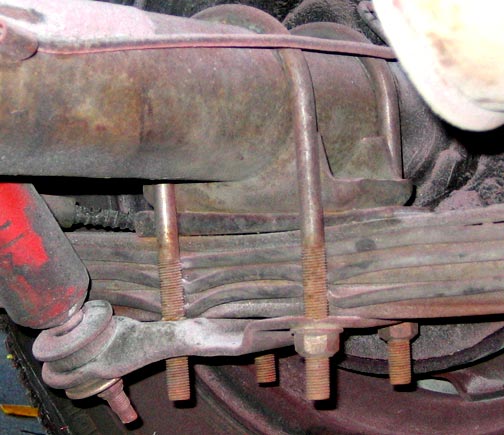

Quick bleeders for brake cylinders ... $8.00 (???) KragenFour lug 8" backing plate flange pattern, same as the 7.25" pattern:

Old shock plate, halfway through modification. I used the American BFH to flatten the end, it is very similar to the much more civilized British VLH. New holes will be drilled in marked spots.

The T5 is a little bulky up top and doesn't sit as high in the transmission tunnel. This causes pinion/driveline misallignment. leading to vibration and U-joint wear. There are two ways to solve the driveline vibration issues, one is to modify the transmission tunnel and get the T5 up to a shallower angle. The other is pinion shims. I didn't feel like hacking the transmission tunnel up so I measured the pinion vs transmission angle, and fabricated some 3.5 degree angle shims. The shaft angle to drive line angle at the U-joint is right at the outside edge of what is considered "acceptable". Still, it's nothing like I've seen in lifted trucks.

Side view.

Top view. Good thing I stamped the finished angle on top. Until I found these pics, I thought it was a 6 degree wedge.

And installed.

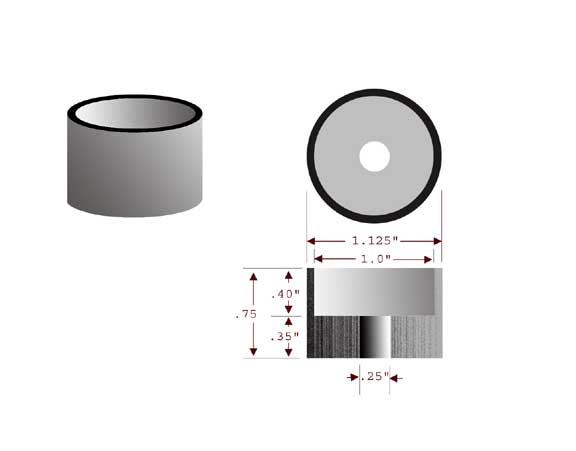

I have an aluminum driveshaft out of Crown Vic cop car that I'll have shortened, but in the meantime, I asked my brother to turn a few adapter cups for the original driveshaft's tiny1" U-joints.Finished steel adapter cups:

The plans for the cups:

I initially had some reservations about using adapter the cups, but comparing the wall thickness of the cups againts the tiny stock U-joint cup wall thickness alleviated any anxiety. After several months of abuse, I replaced the steel drive shaft with the modified aluminum shaft. The cups showed -zero- sings of wear or distortion, and measured exactly the same as when I installed them.

I found the very nice aluminum driveshaft at the pick'n'pull when I was getting the jag filler cap cups. It's out of a Crown Victoria cop car.

It required shortening a few inches and some crossover U-joints. This is a 1330 (shaft) X 1310 (8" rear) crossover U-joint (obvoiusly from King Bearing Co.).

The slip yoke is for an S10 T5.

The Kind Folks at TRACY 24 HOUR DRIVELINE in TRACY, CALIFORNIA, (209) 836-0828, decided I didn't need the nearly new, heavy duty AOD slip yoke that was on the police driveshaft, and KEPT IT FOR THEMSELVES, when they installed the GM splined slip yoke.

The shop workers do decent work, but the managment guys are, in my humble opinion, a bunch of dirtbag rip-off ex-carni illiterate trash low-life thieves. No more business from me, ever. I'll drive to another f***ing state to avoid deaing with those a**holes again. ANYBODY I talk to with a driveline issue, in person, or on any of the many automotive forums I participate in, I'm going to make my opinion known. And I can be quite convincing.